June 16, 2025 – A groundbreaking new type of reversible adhesive that cures under visible light in seconds and can easily be debonded using a kitchen microwave has been developed by researchers at the Hebrew University of Jerusalem.

The study was published in the high-impact-factor journal Advanced Materials, and was authored by Prof. Shlomo Magdassi and Ph.D. student Natanel Jarach of the Hebrew University Institute of Chemistry and Center for Nanoscience and Nanotechnology, along with Prof. Hanna Dodiuk of Shenkar College for Engineering, Design and Art.

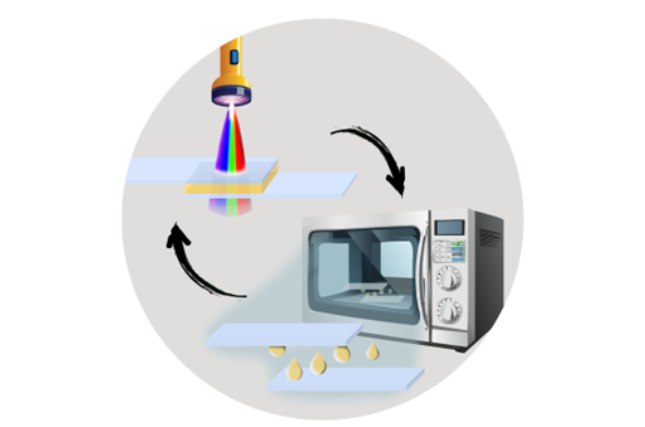

“You can bond glass to metal or plastic in seconds, and when you’re done, debonding it with a kitchen microwave,” said the authors. They demonstrated that over 90% of the material could be recovered after just 30 seconds of microwave exposure. Still, the adhesive retains its mechanical, thermal, and optical properties after multiple cycles of bonding and debonding.

Over 90% of the $92.6 billion global adhesives market relies on thermosets: polymers and plastics, like epoxy and silicones, which form irreversible bonds and accumulate in landfills. Even recyclable alternatives, like reversible adhesives based on dynamic covalent chemistry, often demand energy-intensive processes like prolonged heating above 150°C, toxic solvents, or deep UV, or they enable recycling only by compromising performance. The answer? A dynamic polymer derived from α-lipoic acid (ALA), a naturally occurring antioxidant, which redefines material lifecycles.

TetraALA’s, the new adhesive’s name, secret lies in its four-armed molecular structure, synthesized via a one-pot reaction between alpha lipoic acid and pentaerythritol. The new adhesive photocured in 30 seconds under visible wavelengths (400–650 nm) and maintained strong adhesion to glass, plastic, aluminum, and circuit board materials (4-6 MPa). Surprisingly, it even functions underwater. The bonding is enabled by dynamic disulfide linkages that lock into place during curing and can be undone with mild microwave radiation: no solvents, no high temperatures.

The adhesive’s optical clarity and high refractive index (1.62) are also suitable for optical applications such as beam splitters. The team also showed that using tap water can enhance bonding strength due to ion exchange effects. Furthermore, they have also demonstrated that this new adhesive has some biomedical potential, achieving 145 kPa shear strength on chicken skin using 630nm light, matching surgical glues but with reversible bonding.

By combining rapid curing, mechanical robustness, and closed-loop recyclability, TetraALA exemplifies a sustainable approach to thermoset-based adhesives. Its compatibility with biomaterials, optical systems, and underwater applications highlights its potential for further advancements in adhesive design and material sustainability.

Future studies should elaborate on the microwave-induced recycling mechanism, employing computational chemistry and other complementary measurements. In view of industrial application of microwave recycling, the proposed approach presents various challenges that should be addressed in the future, for example, suitability to a variety of substrates and to non-planner substrates, and the optimal ways for recovering the recycled adhesive from the bonded laminates.

The research paper titled “Untying the Knot: A Fully Recyclable, Solvent-Free, Wide-Spectral Photocurable Thermoset Adhesive” is now available in Advanced Materials and can be accessed here.